User Controls

3d printing general thread

-

2019-12-04 at 11:18 PM UTCAnyone else fuck with trendy science plastics? I'm learning it and trying to build a company around it (to build one specific automotive related part that can be customized) and I'm having a hard time with autodesk. Not intuitive at all for me in terms of customizing designs and getting scale correct. I'm buying two more printers sometime before christmas but should get chinky with autodesk first. Killed tinkercad and just need to fine tune designs. Anyone know of any good resources for getting better at this kinda thing. Basically we're going to be marketing the product (and the customizable manufacturing potential) like we have it figured out and can bang shit off all day, but with something that would likely require minor detail changes between orders, it can be annoying. I also need a better business partner because the current one I have is kinda out to lunch. Also the TPE's we're using could use more flexibility.

That's just what I'm going through right now. This thread is for all things 3d printer related, from guns to dildos. I think it's the only thread I've made outside of GS and it will get 0 repliesThe following users say it would be alright if the author of this post didn't die in a fire! -

2019-12-05 at 12:23 AM UTCI have often thought of getting one just to fool around with so I could prototype filtration components for my fish tank.

The future of 3d printing is also changing,it used to be just the filament type now you can get the resin SLA printers that I think are very cool.

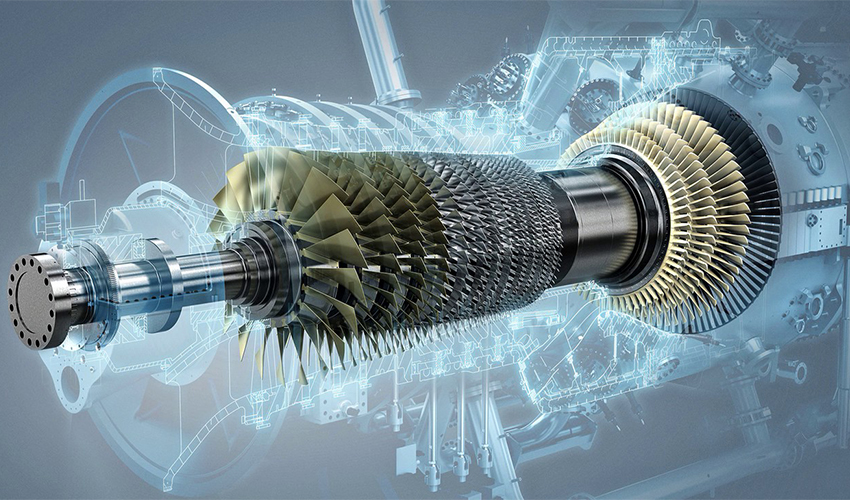

Then there is the sintered metal type,VERY COOL.

And very expensive at this time but hey the price of stuff always goes down.The following users say it would be alright if the author of this post didn't die in a fire! -

2019-12-05 at 12:36 AM UTCI help people out with 3d modelling issues weekly! I'd love to pitch in if you're having some hiccups.

though I only work in solidworks unfortunately :( I can help you out in that environment, or you can send me the stp/stl to do something with

side note: if you're looking for practical quality, probably the best standard home level printer is the prusa i3 mk3s but depending on the budget there are some really solid lower price options.

here's a strange stand I made up for someone last week: The following users say it would be alright if the author of this post didn't die in a fire!

The following users say it would be alright if the author of this post didn't die in a fire! -

2019-12-09 at 10:52 PM UTCMine collects dust.

-

2019-12-09 at 10:57 PM UTCconsidered buying a 3D printer that has interchangeable laser/CNC cutting heads but the work area is small and I didn't really want to spend that much money on it

-

2019-12-09 at 11:02 PM UTC

Originally posted by AngryOnion Then there is the sintered metal type,VERY COOL.

And very expensive at this time but hey the price of stuff always goes down.

It's also interesting because scintered powdered metals tend to be stronger than most mass-produced casting methods, and 'printing' is inherently less wasteful that methods like CNC cutting -

2019-12-09 at 11:03 PM UTCYou can't just print an object. For instance, with aluminium, ideally it should be CNC'd out of a solid block, then properly annealed.

3D printed guns just fall apart after just a few shots due to the weak atomic structure.

3D printing aims to replace a thousand years of metallurgy and experience with buzzwords. Not a good idea. -

2019-12-09 at 11:08 PM UTC

Originally posted by Star Trek VI: The Undiscovered Country You can't just print an object. For instance, with aluminium, ideally it should be CNC'd out of a solid block, then properly annealed.

3D printed guns just fall apart after just a few shots due to the weak atomic structure.

3D printing aims to replace a thousand years of metallurgy and experience with buzzwords. Not a good idea.

https://www.extremetech.com/extreme/170574-the-worlds-first-3d-printed-metal-gun-is-a-beautiful-45-caliber-m1911-pistol -

2019-12-09 at 11:15 PM UTC

Originally posted by aldra https://www.extremetech.com/extreme/170574-the-worlds-first-3d-printed-metal-gun-is-a-beautiful-45-caliber-m1911-pistol

Can it 3D print without costing hundreds of dollars?

How about without smelling like cancer?

Article doesn't even make survivability estimates when looked at closely. -

2019-12-09 at 11:29 PM UTC

Originally posted by Star Trek VI: The Undiscovered Country Can it 3D print without costing hundreds of dollars?

How about without smelling like cancer?

Article doesn't even make survivability estimates when looked at closely.

That's just to say it's possible, will take a while to actually be affordable like regular 3D printers were.

In terms of high-stress parts like the barrel and the chamber traditional methods like cold-rolling and specific heat treatment will probably always be better, but this just goes to show that it's entirely viable and not just for weapons. I think the main benefit is that it's an additive process of shaping, so there's zero waste compared to all the offcuts in standard methods. -

2019-12-10 at 12:28 AM UTC3d printing is new tech that has a billion problems with it rn. People aren't focusing on the R and D and mostly focusing on the applications because given infinite possibilities of objects to make, all that's feasible are guns and mugs

The Plastics used are horrible for the environment and brittle too, which is why we're using thermoplastic elastomers which aren't as bad but are still shitty. We have a product we can make with the current tech so we're trying to make it work. I have faith in the process despite the culture of it being completely neckbearded. I like the idea of "makerspaces" but it's still kinda cringey to be trying to instill punk rawk ideals into making some plastic bullshit. Guns r cool tho but I would never bring one to a shoot outThe following users say it would be alright if the author of this post didn't die in a fire! -

2019-12-10 at 12:34 AM UTCyeah I think 3d-printing plastics is more a development stepping-stone than anything else, actual real-world applications are limited

-

2019-12-10 at 4:13 AM UTC

Originally posted by Star Trek VI: The Undiscovered Country You can't just print an object. For instance, with aluminium, ideally it should be CNC'd out of a solid block, then properly annealed.

3D printed guns just fall apart after just a few shots due to the weak atomic structure.

3D printing aims to replace a thousand years of metallurgy and experience with buzzwords. Not a good idea.

printing a gun reciever on a consumer level 3d printer is like asking india to colonize mars.

there has* been* substantial improvements in the past 5 years, such as near perfectly spherical titanium aluminide additives (!?!) [https://equispheres.com/], as well as carbon fiber impregnated thermoplatics [https://markforged.com/]

just like most problems, keep throwing money at it until its gone.

here's a cool (and econ. justified) application example for an industry that can afford it:

'weak atomic (micro)structure' in early development was a huge hurdle. mainly due to crack propogation when subject to eccentric combined loading. this was due to what you said.

however the 'mid' ranged machines now advertise an isotropy (homogeneous strength about all directions) of +95% in the worst case scenarioThe following users say it would be alright if the author of this post didn't die in a fire! -

2019-12-10 at 4:25 AM UTCi remember trying to learn autocad and it was so fucking boring so i went to the bathroom and did a line of meth and then sat in the library fucking with it for like 11 hours straight. i was a lot more familiar with it after that.The following users say it would be alright if the author of this post didn't die in a fire!

-

2019-12-11 at 2:31 PM UTCHere is a link for a new type of 3-d printer.

Very interesting.

http://ninetymilesfromtyranny.blogspot.com/2013/12/a-10000-3d-printer.html

It uses salt water to control the z axis.